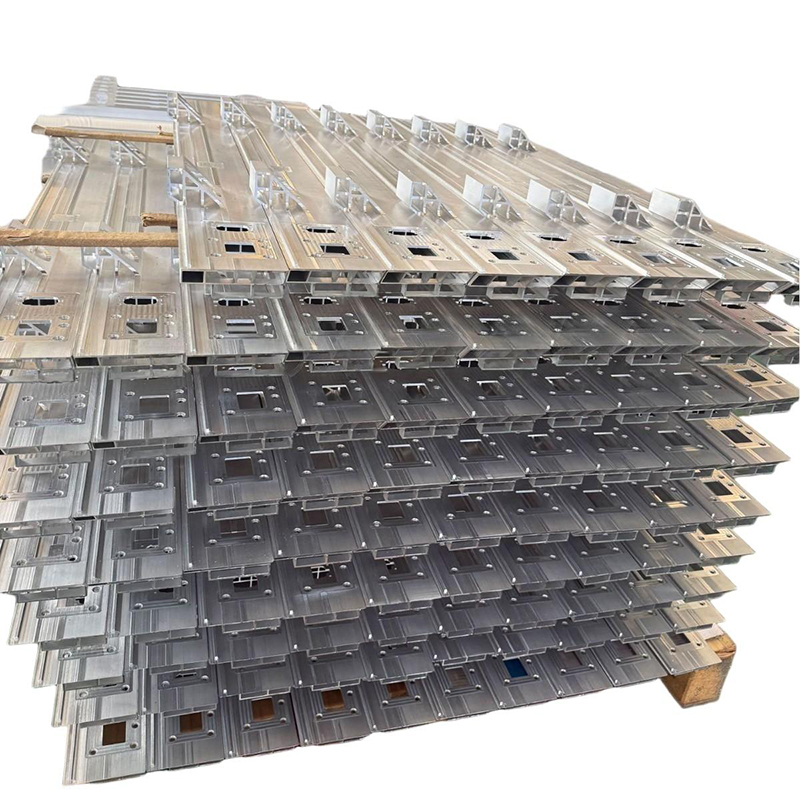

Exterior wall steel structure hangers

Solution

Solution

Our galvanized carbon steel sheets meet the highest industry standards. Each part is robust, reliable, and tailored to your unique needs based on our advanced stamping technology and experience.

Quote Inquiry >

Exterior wall steel structure hangers

Aluminum-magnesium-zinc coated steel sheet has excellent resistance to high corrosion and a self-healing surface, making it the best material for exterior wall decoration and protection.

- Length can be customized according to customer needs.

Industry Applications

Our mission is to provide best-in-class metal stamping and metal forming solutions for the most challenging and innovative engineered product designs. We serve a wide range of market sectors by combining advanced metal stamping production and tooling equipment, superior quality control, seamless automation and production processes, and a knowledgeable and experienced team.

- Aerospace

- industry

- ocean

- medicine

- Building decoration

- car

- illumination

- Electronics

Precision Stamping, Smart Manufacturing for the Future

Your one-stop metal stamping solutions expert

Your one-stop metal stamping solutions expert

Quality assurance

Quality is our top priority. We conduct a feasibility review at the beginning of each project to ensure the manufacturability of the part. A full-speed run study is also performed during the first production run to ensure quality before mass production. This enables our quality and production management teams to closely monitor control measures to ensure a smooth production process. Once testing and inspection pass and the first batch of qualified parts are produced, production continues.

Our quality management system consists of advanced quality technology and controls, a continuous improvement program, and an exceptional quality laboratory and management team. We deploy camera vision systems and sensor technology in our production facilities, designing and manufacturing unique systems for each production project. Our vision system technology works in harmony with our stamping production machinery, thoroughly inspecting and identifying part features and dimensions through automated camera imaging. This quality control process ensures that every part produced using our stamping equipment is 100% qualified and defect-free.

Power your applications more efficiently with high-performance busbars. With a dedicated team, innovative equipment, and superior quality control, we provide high-quality services tailored to each customer's unique needs.

Our quality management system consists of advanced quality technology and controls, a continuous improvement program, and an exceptional quality laboratory and management team. We deploy camera vision systems and sensor technology in our production facilities, designing and manufacturing unique systems for each production project. Our vision system technology works in harmony with our stamping production machinery, thoroughly inspecting and identifying part features and dimensions through automated camera imaging. This quality control process ensures that every part produced using our stamping equipment is 100% qualified and defect-free.

Power your applications more efficiently with high-performance busbars. With a dedicated team, innovative equipment, and superior quality control, we provide high-quality services tailored to each customer's unique needs.

Stamping products

Explore other materials

English

English 中文

中文